HIGHT QUALITYHigher quality and more accurate products by our better and more precise control technology.

Now adays thin plate cold rolling mill requires rolling quality that produces thinner and higher precision plates.

We are proud to be known as innovators in the rolling mill industry, and we are always looking ahead for challenging new technical developments. Our precise plate thickness and shape control skills make full use of our intermediate roll shifter and Double AS-U function, which allow us to meet today's requirements for high quality products based on improved plate thickness and shape precision.

Sendzimir 20 High Mill and Sendzimir Z-High Mill bring these advanced technologies to modern manufacturing facilities

Advantage of SEJAL is the efficient worldwide network. One of our honors is the lots of supply record of Sendzimir mills.

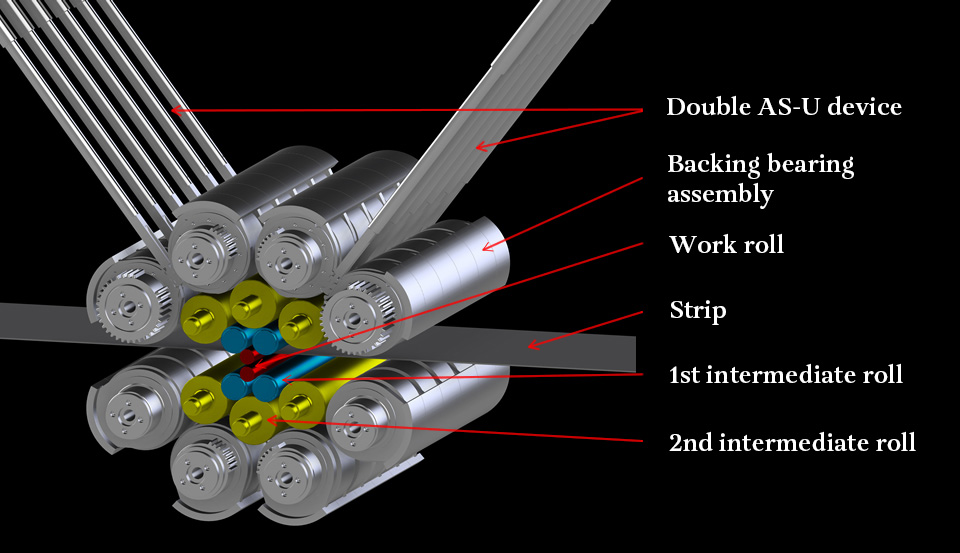

Sendzimir 20 High Mill

Feature of 20 High Mill

A cluster type configuration of 20 rolls enables to use smaller size work rolls, that allow high reduction rolling of hard metals and the production of thinner gauge strips.

The newly developed technologies of Double AS-U and lateral shifting of 1st intermediate roll are famous for the ability to produce excellent flat strip.

The high rigidity of zero crown mono-block housing or a pre-stress split housing and high response of hydraulic screw down system realize the production of strip having superior thickness gauge accuracy.

In case of pre-stress split housing, opening value of top mill housing is large and operation characteristics is good.

Work roll can be easily and quickly changed, as work roll is of simple shape and without chocks and neck bearings.

Changing to new work roll at the last pass of a rolling results excellent strip with splendid surface luster.

Structural figure

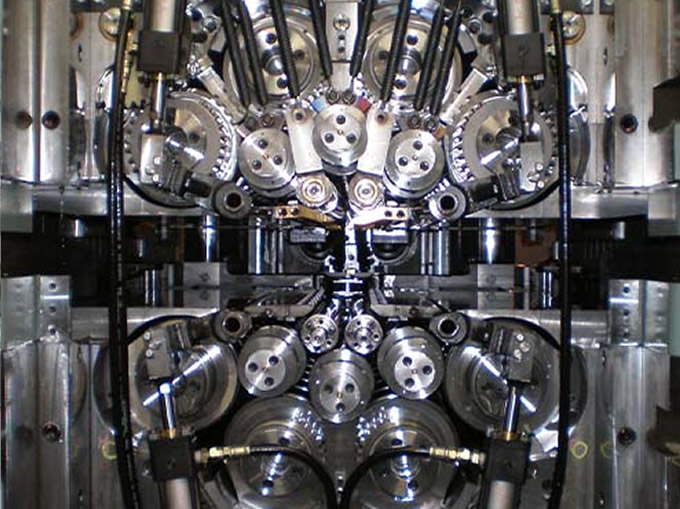

Sendzimir Z-High Mill

Feature of Z-High Mill

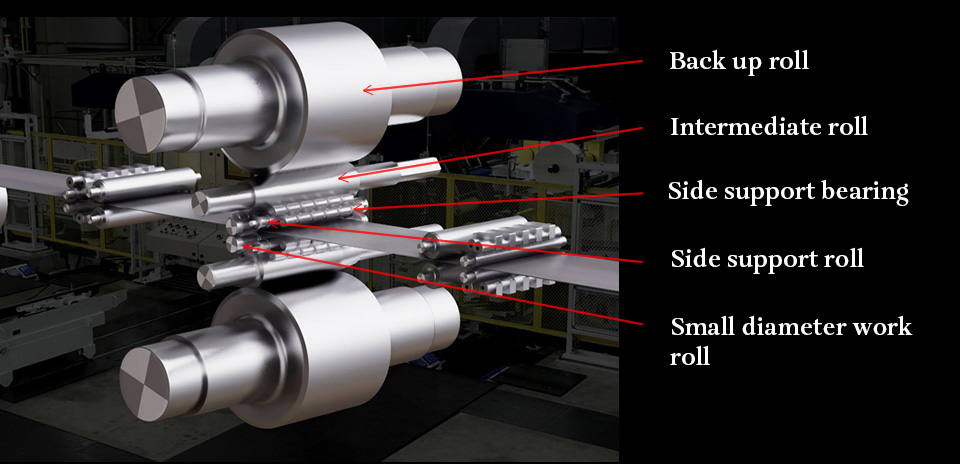

Rolls are consisting of back-up roll, intermediate roll and smaller work roll supported by a cluster of side support rolls. The smaller work roll enables high reduction, harder and thinner strip rolling. By the functions of lateral shifting and bending of intermediate roll, very flat strip can be easily produced. Work roll can be easily and quickly changed, as work roll is simple shape and without chocks and neck bearings. Changing to new work roll at the last pass of a rolling results excellent strip with splendid surface luster. The materials of work rolls can be selected corresponding to the materials being rolled. Easy-to-modify a conventional 4-high or 6-high mill into Z-high mill.

Structural figure

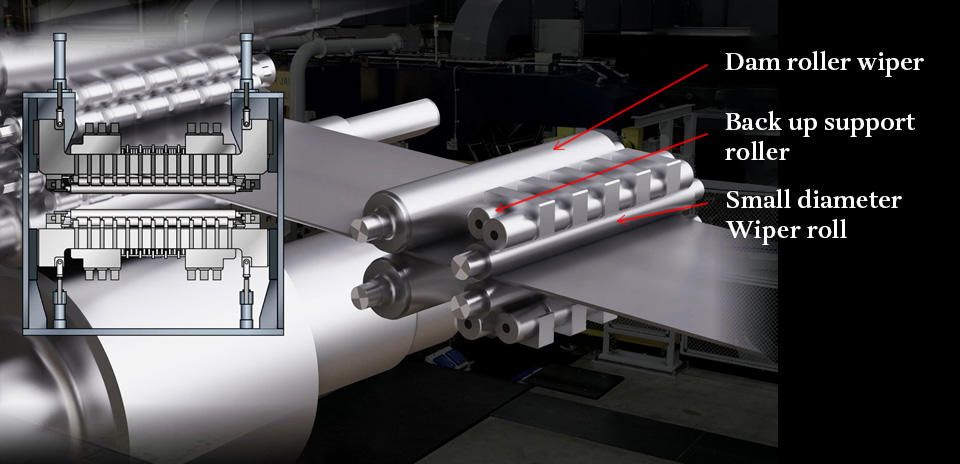

Sendzimir Z-Wiper

Feature of Sendzimir Z-Wiper

Small diameter wiper roll achieves good strip wiping.

Widthwise uniform wiping is realized, because each wiper roll supported by axially divided supporting rollers gives uniform pressing force onto strip.

Productivity of the mills is greatly improved, because cleaning or replacing of wiper roll for each coil is not required.

The existing wipers can be, easily and in short time, replaced to Z-Wiper, because the space required is quite small.

Structural figure